Estimation of Suitable Condenser for Batch Distillation in Glass lined reactor

In API and Fine Chemicals production, Batch Distillation technique is employed frequently to remove solvent or for reaction under-reflux reactions. Glass Lined reactor is used for Reactions, and for distillation Steam is employed in the Jacket of the reactor to supply the energy needed to Evaporate Solvents. Many times our customers asked for a Suitable condenser required for distillation on Glass Lined Reactor (GLR Reactor). So UD Technologies writes a blog on the Estimation of Condensers for GLR Reactor. The following technique relies on Basic heat transfer principles and shows different factors related to deciding the Heat transfer area of the condenser for Batch distillation.

One has to remove the same energy in the condenser from vapors by coolant. The Heat transfer area of the Condenser for Glass Lined Reactor can be estimated by following the formula

For Reactor Jacket:

Q1 =U1 X A1 X LMTD1

For Condenser

Q1= U2 X A2 X LMTD2 (As Energy is to be removed in the condenser is equal to the energy supplied to the Solvent for evaporation in the reactor jacket.

U1 and A1 can be found in the literature of GLR Manufacturer’s catalog

U2 can be get from Glass Shell and Tube Heat exchanger

LMTD1 can be found from the Steam Saturation temperature and Boiling point of the Solvent under the Operating temperature

LMTD2 can be found from the Condensation temperature and Outlet temperature of Condensate.

The following points are to be considered

- In Heat duty estimation cross-check, reflux load is to be considered

- In the Estimation of the condenser, different Heat transfer coefficients for different process duty is to be considered. For, Example Heat duty in Desuperheating, condensation, and subcooling

- Heat transfer area reduces with the removal of Solvent from the reactor, so this calculation is for the full reactor and for Maximum Heat Duty and Area

From Above equations

A2 = – (U2 X A1 X LMTD1 )/( U1 X LMTD2)

Please note that this estimation technique gives you a nearer Heat transfer Area. But certain excess areas shall be considered to include errors due to the Process part and assumed Heat transfer coefficient. Further, it is to be noted that this estimation is for particular reactor and process duties.

Case Study on estimation-of-condenser-for-Glass lined Reactor

Methanol is to be distilled at atmospheric pressure in 2KL Glass Lined Reactor and the same vapors are to be condensed in the Overhead condenser and condensate is to be collected in the receiver. Saturated Steam is to be used 3 Bar G . Chilled water inlet temperature is 10 deg C and Exit temperature considered is 15 deg

U1 =200 kcal/Hr-M^2- deg C

A1= 9.1 Sq. Mt-From Catalog of Manufacturer (for AE type reactor)

Saturation temperature of Steam — 144 Degc-(From Steam Table)

Boiling Point of Methanol at Atmospheric Pressure – 65 deg c

LMTD1 – 144 -65 = 79 DEGC

U2= 150 KCAL/HR-Mt2-degc

LMTD2 = (65- 15) – (65- 10)/LN (65-15)/ (65-10) = 52.46 DEG C

A2= Heat transfer area of Condenser = (200 *9.1*79)/ (150 * 52.46) = ~18.3 Sq. Mt

Please contact [email protected] while selecting of the Proper Condenser as the Heat exchanger area varies considerably with Process.

A similar method can be used for employed for Different Materials of construction of Heat exchanger tubes and also for SS304 Reactor and SS Condenser

Precaution using the above technique on Estimation of Condenser for GLR Reactor

Please note that this estimation technique gives you a nearer Heat transfer Area. But certain excess areas shall be considered to include errors due to the Process part and assumed Heat transfer coefficient. Further, it is to be noted that this estimation is for particular reactor and process duties.

Please note that this estimation technique gives you a nearer Heat transfer Area. But certain excess areas shall be considered to include errors due to the Process part and assumed Heat transfer coefficient. Further, it is to be noted that this estimation is for particular reactor and process duties. Please take necessary decisions for an Appropriate area considering reducing volume in the reactor and the heat sensitiveness of Process Material.

Kindly contact us at [email protected] or on +91-7990397491 for any questions

Please visit the following weblinks related to Glass Lined Reactor

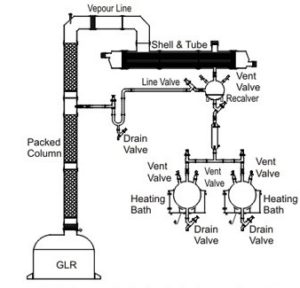

Distillation set up over Glass Lined Reactor